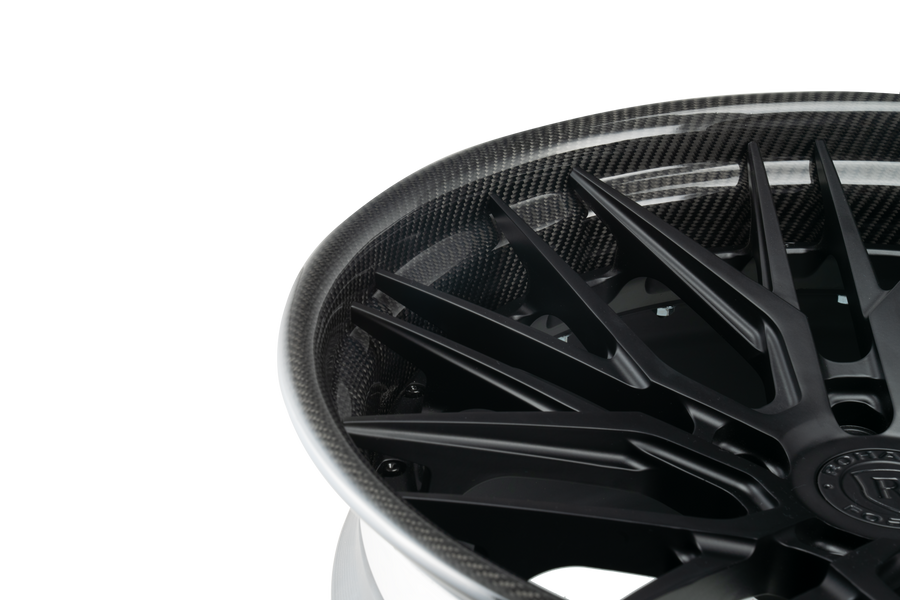

Rohana’s Carbon Series, in collaboration with Dymag, is the peak level of automotive excellence. Carbon fiber is lighter than traditional materials used for wheel barrels such as aluminum, reducing the un-sprung weight of the vehicle and because it is a resistant material it can withstand the harsh conditions and stress making it the best option for high-performance driving.

Carbon fiber has a high strength-to-weight ratio, making it a durable option for wheel barrels. The reduced weight and improved strength of the barrels result in improved acceleration, braking, and handling performance.

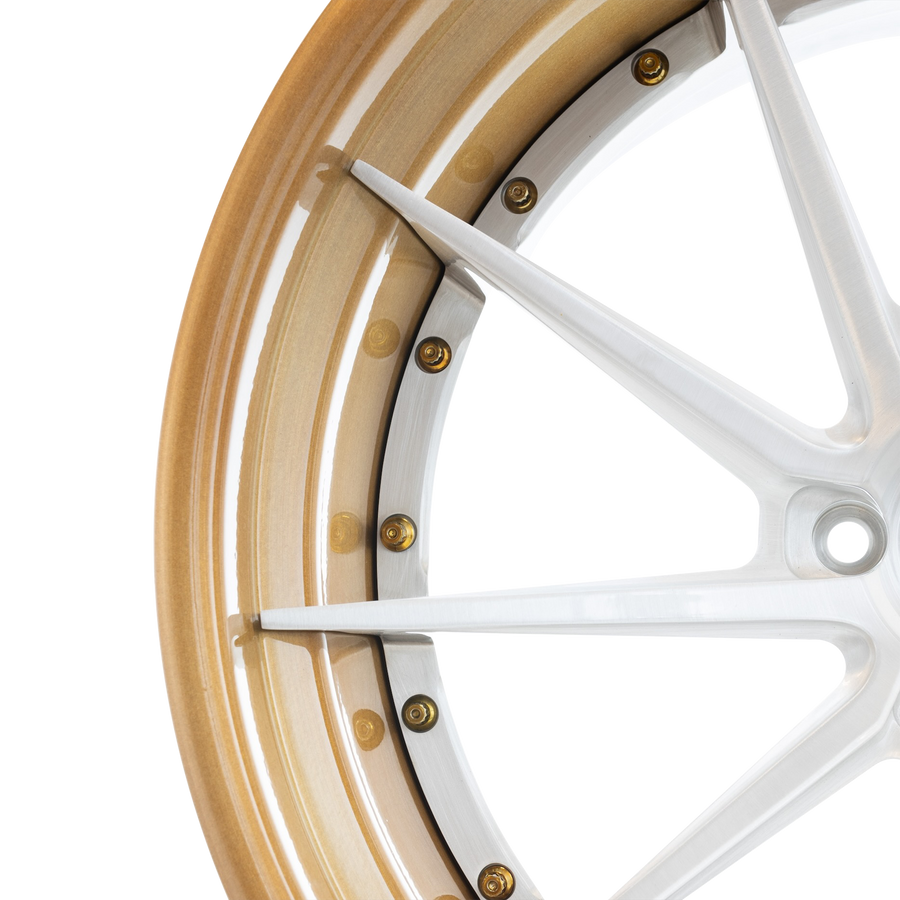

Nearly 25% lighter than aluminum barrels, the Carbon Series falls under our Tandem option allowing for modular customization to the face and hardware.

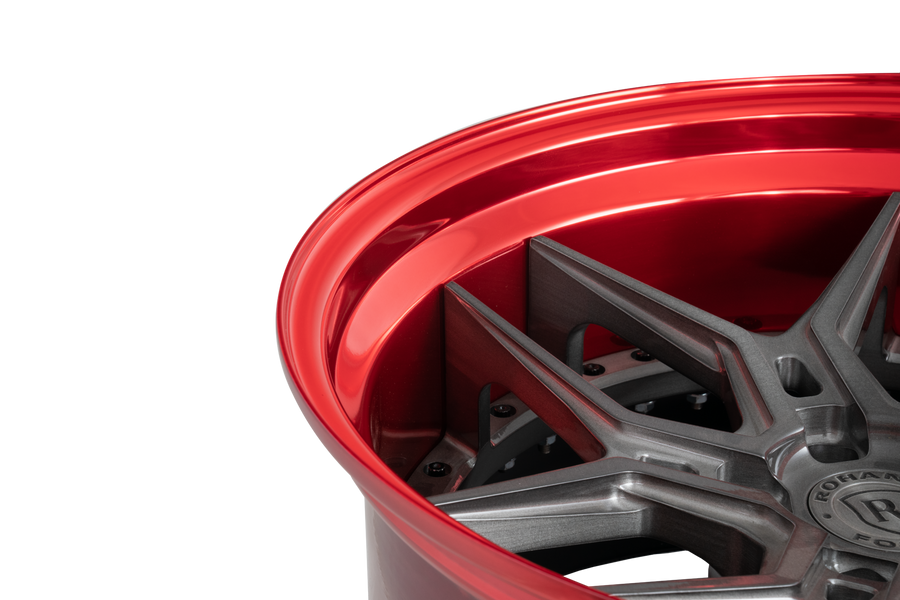

Rohana’s Aero Forged series blends advanced forging technology with aerodynamic-inspired design. Engineered for maximum strength and reduced weight, each wheel delivers precise fitment and a bold, modern profile.

Available in both one-piece and four-piece construction, the aero-disc allows for full customization while maintaining the structural integrity demanded by high-performance builds.

Our 3D Forged Center Cap is constructed from two individually machined pieces and delivers a true layered 3D effect that elevates every forged wheel with added depth and dimension.

Each piece can be finished independently, enabling unique color combinations and contrast options that elevate the center cap from a simple detail to a defining design element.

The design process is an important step in the creation of a forged wheel as it sets the foundation for the entire production process. It involves careful consideration of various factors to ensure that the final product is not only visually appealing, but also functional and safe. Each design is engineered for brake clearances and undergoes a Finite Element Analysis (FEA) specific to the vehicle.

During the lathe process, the wheel blanks, which are cylindrical pieces of aluminum that have been pre-formed, are mounted on a lathe machine and rotated at high speed. A cutting tool, guided by the lathe machine, removes material from the wheel blanks to shape them into the desired wheel design. The precision of the lathe process is critical, as it determines the wheel’s accuracy and stability. The final product is a wheel that has a precise shape, a consistent thickness, and a smooth surface finish.

The CNC milling process is controlled by a computer program that uses precise algorithms to ensure that the wheel blank is cut to the exact specifications outlined in the design blueprint. This process is highly accurate and can produce complex and intricate shapes with ease. The result of the CNC milling process is a wheel that has a precise shape and a smooth surface finish, ready for further processing and finishing.

The engraving process is a final step in the production of our forged wheels. During the engraving process, decorative designs or logos are cut or etched into the surface of the wheel using specialized tools. This process can add a unique touch to the wheel and create a custom look that sets it apart from others.

After sandblasting off any leftover residue from the engraving process, the wheel is powder coated and clear coat is applied, to protect it from corrosion and other environmental factors. This step not only enhances the appearance of the wheel, but also extends its lifespan and maintains its overall quality.

During the assembly process, the individual components of the wheel, such as the face, the inner barrel, and the outer barrel, are brought together and securely fastened to create a single, complete wheel. Once the assembly process is complete, the wheel is subject to various tests and inspections to ensure that it meets the required standards and specifications.

Rohana Forged is designed and engineered to achieve the maximum concavity without any compromise to drivability. Our designers have gone through countless hours where every detail has been accounted for to provide you with the most innovative designs.

Each wheel is made to order and manufactured in a state of the art facility, sourcing only the best materials from aerospace grade 6061-T6 aluminum to grade 8 fasteners and goes through an extensive program where utmost quality is a requirement. Rohana Forged is tailored to you where we make your conception into a reality.

Please fill out the form below to request a custom wheel build. Choose your application and finishes.